Why Smart Temperature Monitoring Matters for Food Safety & Compliance

Temperature control is one of the most overlooked, yet critical, elements in food safety compliance, cold-chain management and hospitality operations. With manual temperature logging still the norm in many kitchens, factories and retail food outlets, the risks are real: food spoilage, product recalls, customer illness, regulatory fines, and damage to a business’s reputation.

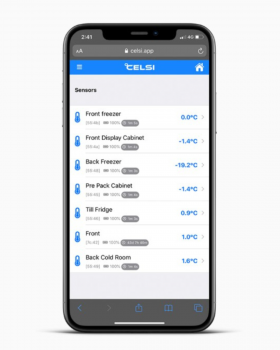

With Celsi’s AI-powered Smart Temperature Monitoring System in place, you can automate continuous logging, receive real-time alerts, identify equipment faults before they turn into stock losses, and generate audit-ready, HACCP-compliant data without manual paperwork.

Below we answer key questions that foodservice operators, food manufacturers and retailers frequently ask, from “Do I really need this tech?” to “Is AI safe?” and “What happens if you don’t comply?”

Frequently Asked Questions (FAQs)

Q1. Is AI safe for use in temperature monitoring and food-safety applications?

Yes. When implemented properly, AI technology is a highly effective and safe tool for food-safety systems. According to multiple industry reviews, AI supports risk prediction, continuous monitoring, anomaly detection and improved traceability in food-supply chains.

Here’s how it works and why you can be confident:

- The system collects detailed sensor data (for example, one-minute temperature intervals in Celsi’s monitoring platform) and analyses trends rather than relying on sporadic manual checks.

- AI helps move operations from reactive to proactive monitoring. Potential deviations are flagged early (for instance, a fridge defrost-cycle issue) and corrective action can be taken before a full failure occurs.

Bottom line: AI-based temperature monitoring is both safe and increasingly standard in food-safety management. It adds reliability, traceability and depth to your compliance and HACCP systems rather than replacing human responsibility.

Q2. Can a business face fines if temperature control isn’t compliant?

Absolutely. Temperature control is a foundational requirement of Food Safety Standard 3.2.2, which governs time-temperature controls under Australian law.

Some indicative penalty figures:

- Across Australian states and territories, food businesses can face fines up to $1 million for serious breaches, and individuals up to $200,000.

- Local enforcement data shows fines for temperature-control or tracking failures, for example, Brisbane City Council issued nearly $600,000 in fines in one year across 56 businesses, many related to improper storage or display of potentially hazardous food.

Implication: Inadequate monitoring exposes your business to financial, regulatory and reputational risk. By deploying an automated temperature-logging system such as Celsi, you strengthen your defence, demonstrate due diligence, and keep audit-ready food-safety records accessible on demand.

Q3. Does a business really need high-tech temperature-control solutions?

Short answer: yes, increasingly so, especially if you value operational efficiency, risk management, and HACCP compliance.

Here are four reasons why:

- Manual logging is time-consuming, error-prone and often fails to capture real-time deviations. Missing a critical excursion, for example, a fridge running warm overnight, can lead to spoilage or unsafe product.

- Modern food-safety audits and internal controls expect detailed records, trending data and proof of corrective actions. Celsi provides real-time data, unlimited alerts, automatic logs and cloud-based history.

- For multi-site food manufacturers, retail chains, or hospitality venues, the cost of failure, e.g. lost stock, product recall, or temporary shutdown, far outweighs the investment in monitoring.

- Competitive advantage: demonstrating state-of-the-art monitoring technology adds credibility with regulators, customers and B2B foodservice clients.

Conclusion: If you handle perishable stock, operate commercial refrigeration, or supply food to other businesses or consumer-facing outlets, then high-tech monitoring is not a luxury, it’s a strategic necessity.

Q4. How does Celsi integrate into a food-safety program (HACCP, compliance etc)?

Celsi is designed to integrate seamlessly into critical-control-point (CCP) monitoring within HACCP frameworks.

- Real-time monitoring supports CCP tracking for storage, transport and display zones.

- Historical data and exportable logs support validation and verification of your HACCP plan.

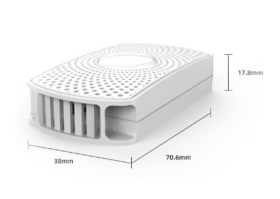

- Wireless sensors allow easy installation without costly infrastructure, ideal for cafés, restaurants, manufacturers, and cold-storage facilities.

In short, the system doesn’t replace your HACCP or food-safety plan; it strengthens and simplifies it.

Q5. What happens if the monitoring system alerts me? Do I still need manual checks?

Yes. The smart temperature-monitoring system acts as a safety net. Alerts notify you if temperatures fall outside safe ranges, a sensor fails, or patterns indicate equipment stress.

You still retain responsibility for corrective actions, staff training, food-handling practices, and maintaining a strong food-safety culture. The advantage is more reliable, continuous coverage, including outside business hours, and full data traceability across all storage zones.

Final Thoughts

In an environment where every degree counts, AI-enhanced temperature monitoring goes beyond convenience; it underwrites food safety, compliance, and operational resilience.

For foodservice operators, manufacturers, and retailers handling temperature-sensitive stock, the risks of relying on manual logging are simply too high. With Celsi Smart Temperature Monitoring, you can shift from reactive risk management to proactive control, protecting your stock, your brand, and your bottom line.

Contact details for Celsi Food Safety Temperature Monitoring

Sign up to the Fine Food Wholesalers newsletter, like us on Facebook or follow us on Instagram to keep up-to-date with new products and services.

Tags: Celsi, Smart Temperature Monitoring, Ai Food Safety, Food Safety Compliance, Haccp Australia, Cold Chain Management, Automated Temperature Logging, Food Spoilage Prevention, Restaurant Safety, Hospitality Compliance, Refrigeration Monitoring, Kitchen Safety Technology, Food Manufacturing Compliance, Foodservice Technology, Australian Food Safety Regulations, Cloud-based Monitoring System, Retail Refrigeration Control, Food Safety Fines, Ai Monitoring Sensors, Compliance Automation