Why High-Hydration Pizza Dough Is So Hard to Make at Scale

And why it matters to eating quality

If you’re shopping around for a white label pizza base solution for your business, don’t do anything until you read this!

In the world of pizza dough, hydration is one of the most influential yet misunderstood variables. If you haven’t heard of the term, you’re probably not dealing in pizza (but maybe you’d like to!) While most commercial pizza bases sit comfortably in the 55–65% hydration range, pushing hydration beyond 80% changes not just the dough’s texture, but the entire manufacturing equation.

This is where Sugo Tu stands apart.

Sugo Tu is currently the only Australian manufacturer operating production-line equipment capable of consistently producing pizza dough at 80–85% hydration. That capability is not a marketing headline. It is a technical achievement that has a direct and noticeable impact on how pizza performs, bakes, and eats.

What does hydration actually do to dough?

Hydration refers to the ratio of water to flour in a dough formula. At higher hydration levels, dough becomes softer, stickier, and far less forgiving. Gluten develops differently. Fermentation behaves differently. Handling requires significantly more precision.

At 80% hydration and above, dough begins to behave almost like a semi-liquid. Most industrial dough lines simply cannot cope with this. The dough tears, collapses, or loses structure long before it reaches the oven. As a result, high-hydration pizza is traditionally limited to small-batch or hand-made environments.

Scaling it reliably is another matter entirely.

Why most manufacturers stop short

From a manufacturing perspective, high-hydration dough presents several challenges:

- It’s difficult to portion and shape without deflating the structure

- It requires tight process control to prevent collapse or inconsistency

- Fermentation must be carefully managed to avoid over-proofing

- Standard pressing and forming equipment often destroys those irresistible internal air pockets

For many producers, the trade-off simply isn’t worth it. Lower hydration is easier to automate, easier to store, and easier to standardise. But it also delivers a very different eating experience.

What does high-hydration dough deliver on the plate?

When high-hydration dough is executed properly, the difference is immediately noticeable.

When executed properly, high-hydration dough delivers several distinct characteristics:

- A markedly lighter, airier crumb

- Strong oven spring with visible internal structure

- A crisp outer shell paired with a soft, cloud-like interior

- A more open, artisanal texture

- A finished base that feels lighter and is often easier to digest

This is the reason chefs and pizza specialists continue to chase higher hydration, despite the complexity.

How Sugo Tu approaches high-hydration manufacturing

Rather than pushing hydration as a gimmick, Sugo Tu has built its process around it.

Their production-line equipment, fermentation protocols, and dough handling techniques are designed specifically to preserve structure at high hydration. The dough is carefully pressed into shape rather than aggressively flattened, helping to protect the air pockets formed during fermentation.

The result is a pizza base that delivers what many describe as the lightest, crunchiest pizza on the market, with a texture often compared to eating a cloud rather than a dense bread base.

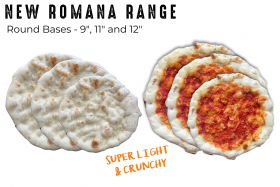

The Romana range as a commercial solution

Sugo Tu’s Romana range is Roman-style pizza dough produced at a minimum of 80% hydration. It’s designed to bridge a gap that many foodservice operators struggle with: achieving artisanal eating quality without sacrificing consistency, efficiency, or reliability in a commercial kitchen.

For operators, this means:

- Predictable performance, service after service

- No need for specialist dough handling on site

- Consistent bake characteristics across different ovens

- An elevated finished product without added labour

Why this matters for contract manufacturing clients

For brands exploring private-label pizza bases and frozen dough solutions, Sugo Tu’s hydration capabilities are not a minor detail. They directly influence how a product positions itself in the market.

High-hydration dough allows manufacturers and foodservice brands to:

- Create lighter, more digestible pizza products

- Differentiate from standard commercial bases

- Deliver an artisanal experience at scale

- Align with premium, quality-driven brand narratives

Not every operation needs 80% hydration. But for those who do, the technical barrier is high, and the options are limited.

HOW TO MAKE YOUR PIZZA CONTRACT MANUFACTURING ENQUIRY

To find out more about Sugo Tu’s pizza contract manufacturing capabilities, reach out today using the contact form and contact details below. It would be great if you would also tell them that you heard about them on Fine Food Wholesalers!